ABOUT THREADS

In the production of carpets, the Tibetan knot uses multilayer yarns. Their number varies depending on the size of the node. Threads are twisted by hand - thanks to this feature of production, we create artistic textures.

When twisting individual yarns of silk and wool, the surface of the carpet becomes softer than when twisting silk, with a gray effect and a noble light sheen. When twisting bamboo and wool, the surface of the carpet also becomes softer and acquires a brighter shine.

We do not use acid for aging threads, because it kills live material. The feeling of genuine vintage arises from the use of twisted yarns, the addition of silk wool and due to special color optical effects.

MANUAL KNOT

The technique of the Tibetan knot appeared in Nepal during the period of the Tibetans' resettlement - they taught the Nepalese people their age-old traditions of carpet weaving.

The essence of the technique lies in the fact that a metal bar is passed through the fractional threads, and nodular loops are placed on it. When the rod is tied with knots, the loops are cut with a knife along the rod - in this case the nap is called “Cat”. If the rod is taken out without cutting the threads, loops are obtained - “Loop”. To change the height of the pile, change the diameter of the rod. The density of the carpet depends on the number of nodes along the vertical and the density of the rows. Measurement is per square inch or per square meter.

1 qd = 2.54 / 2.54 cm

080 nodes on 1kv.d = 124000 1kv.m nodes at

100 knots at 1kv.d = 155000 1kv.m nodes at

150 knots at 1kv.d = 232,500 knots on 1Q . m

200 knots on 1kv.d = 310000 nodes on 1 sq. m

300 nodes on 1 kv.d = 465000 nodes on 1 sq.m

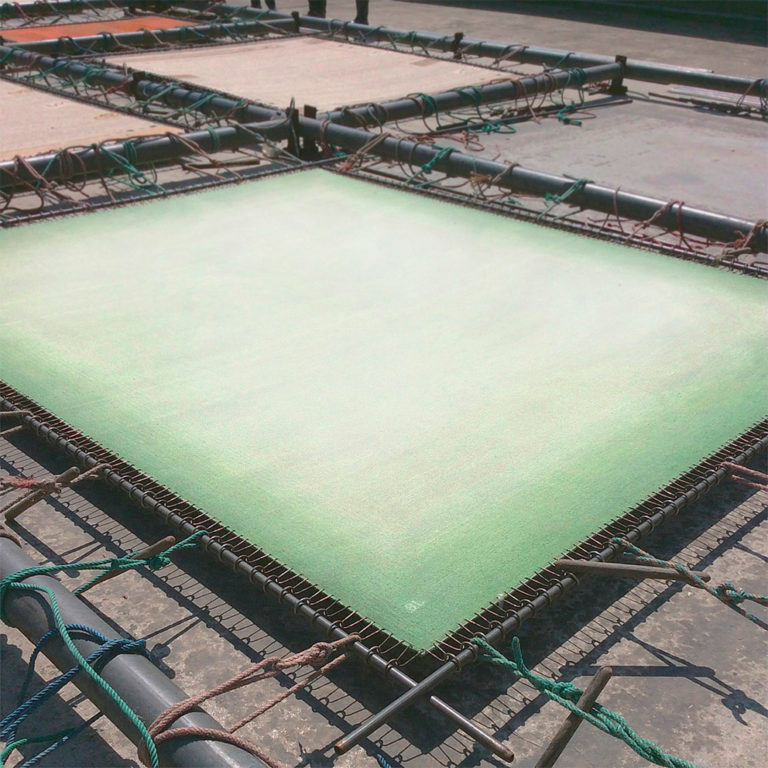

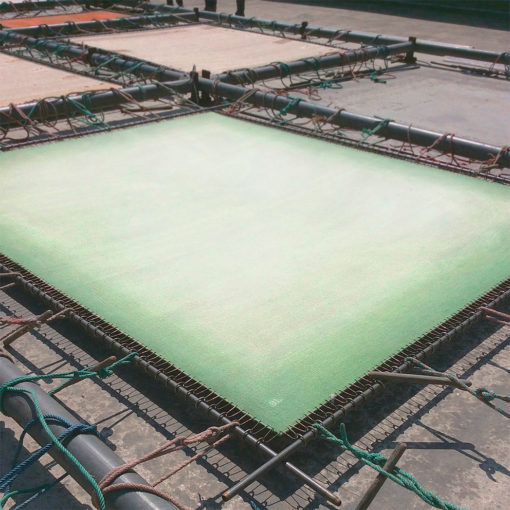

WASHING

Washing the carpet is made by special Swiss eco-friendly soap compositions and mountain water. Carpet dipped into the pool with water, then spread out on a concrete surface and within one to two hours, periodically pouring water over the carpet with soapy water, carefully scrape it with wooden shovels, and then carry to dry to stretch.

STRETCHING

On four sides, the carpet is fixed with hooks inside a metal frame, and in order to fix the shape, it is impregnated on the back side with a thin layer of glue - this is a mandatory step for all Nepalese carpets. We use only water-based glue, it is not harmful to health and has no smell. Glue is used to a minimum, so the shape of our carpets is not always perfect, but here we proceed from our philosophy, trying to preserve the naturalness of the product as much as possible.

A HAIRCUT

After drying, the carpet must be mowed: this is one of the most important final processing processes - at this stage all knitters' mistakes are eliminated. If necessary, replace poor-quality or erroneously located nodes. The contour is cut with a single or double groove to underline the line pattern. If the pile is of different heights, only high pile contours are cut. If the pile height is the same, we additionally grind it with a manual machine, then the carpet comes out perfectly smooth. Design with a clear repetitive geometry or with a large number of identical circles is one of the most difficult to produce, as knitter errors are immediately noticeable. We trust the manufacture of carpets with such drawings to the masters of the highest qualification.

Via BIGLI 15, 20121 MILANO, ITALY

P.IVA/C.F. 05454400960

Thank you for your subscription.